Making Punched Rings For Mail Armor

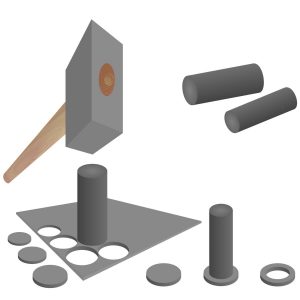

Solid rings can be punched out of sheet metal much like modern washers. As they are already closed, punched rings can be interlinked with riveted rings to form mail. Punched rings are manufactured like this:

- Forge metal to a sheet of 1mm to 1.5mm strength

- Punch a circle out of the sheet

- Punch a 1mm to 1.5mm smaller circle out of the circle

- Sand sharp edges off

The punching steps can be done in a different order. The two steps could even be done at once with an appropriate tool. The punches are hardened steel cylinders.

Why did not all mail contain solid rings?

There are finds of mail with riveted and solid rings throughout the ages. Especially Roman mail was made in riveted-solid fashion. It can help to reduce weight and manufacturing time. However, during medieval times a fashion of pure riveted rings mail gained popularity. Here are some of my thoughts and speculations about the use of this riveted-riveted mail:

- The method of punching was forgotten: This is very unlikely since coins were still punched.

- Riveted rings were stronger: This is very unlikely because rivet heads can be a weak spot. If for some reason wire was stronger than sheet metal, punched rings could have been made a bit thicker. Not having a rivet head makes punched rings less heavy than riveted rings, even if they are slightly thicker.

- Dealing with two raw products was too much hassle: For solid-riveted mail, medieval manufactures would have to get access to both wire and sheet metal. Those precursors are produced more efficiently when craftsmen can commit to specializing. This means collaboration and trade between many people. Yet a big network of collaboration requires sufficient economic and political stability. If that is not given, a smaller network of craftsmen might be better off dealing with just one precursor of material. I think that is likely for medieval times.

- Dealing with scraps was too much effort: When chainmail rings are punched out of sheet metal, typically 30% of the sheet material is used for rings. 70% of it is cut to small scraps of metal. Since metal was very precious in medieval times, it needs to be recycled in order to be economically viable. The sheet scrabs could theoretically be used to form rivets. Yet in the riveted-solid mail, rivets only make up 5% of the mail’s mass. For this wire scraps are enough. Thus the remaining sheet metal scraps weigh more than the finished riveted-solid product! Think of a 6kg mail shirt and a 7kg pile of metal scraps! The scrabs have to be welded or smelted together for recycling. This is laborious and needs to be done by a specialized craftsman. In combination with the thought above, this is likely to be the reason behind the prevalence of riveted-riveted mail.

Drifted Rings:

There is another method of making solid rings. It is quite convincing regarding its low amount of waste: Discover the article and video about Drifted Rings.

Read about Welded Rings.

Or buy Solid Rings.